WHY CHOOSE MICROVAL LAB TECHNOLOGIES

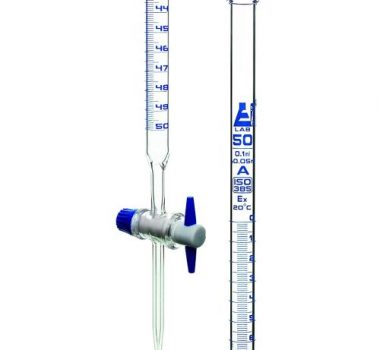

Unfortunately though, so few laboratories or text books contain the correct procedures for calibration of volumetrics. Everyone should know to take into account temperature variations on the water and glassware, but how many people take into account the different shrinkage rates between Borosilicate glass and Soda Lime glass. With Borosilicate’s tighter molecular structure than Soda Lime glass it is less responsive to changes in temperature resulting in minimal thermal expansion which needs to be taken into consideration when testing calibrations. So how do I tell them apart I hear you ask. As a general rule Soda Lime glass is labelled in amber stain, while Borosilicate glass not being able to be stained successfully with conventional amber staining techniques, will be labelled in white or blue ink. Some brands such as Duran are a trade name for Borosilicate glass 3.3, so these will all be in Borosilicate.

Calibration procedures are also influenced by air pressure and temperature at the time of reading, regardless of what type of glass you are testing. By measuring a barometer reading and calculating the air temperature the results may be used in an “Air Pressure And Temperature Correction Table” to obtain a correction figure which is taken into account to obtain a final gravity result to ensure a consistently accurate result is obtained.

We strongly recommend that to comply with good laboratory practice, all Class A volumetric glassware should be check calibrated on receipt. If you consistently find that the glassware falls outside the Class A tolerances for accuracy or delivery time, it should be sent back to your supplier.

For your convenience we at MICRO-VAL have collated all of the relevant procedures and tables from ISO Standards and British Standards We aIso offer a variety of flexible delivery options, including a pick-up and drop-off service, or you can send us your equipment directly.

Interested in getting your measurement and volumetric calibrated? Give us a call or use the contact form on this page to get in touch.

Book our Calibration Services

If you would like a quote or further information about our SLAB Calibration Services, please click here to contact us and arrange an appointment. We look forward to being of assistance.

Volumetric Apparatuses