Why Choose microval lab technologies

At WAGA, we understand that time away from your equipment leads to lost productivity, particularly if your equipment is used day-to-day in your work. That’s why we aim to calibrate and return your equipment as quickly as possible.

We also offer a variety of flexible delivery options, including a pick-up and drop-off service, or you can send us your equipment directly.

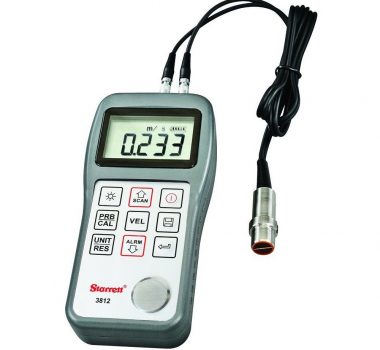

Interested in getting your measurement and dimensional tools calibrated? Give us a call or use the contact form on this page to get in touch.

Book our Calibration Services

If you would like a quote or further information about our SLAB Calibration Services, please click here to contact us and arrange an appointment. We look forward to being of assistance.